MTMS100 series double axis stages

1.Actuated withhigh precisionball screw rodandcross

roller guides.

2.Compact design with highorthogonal

precision of the two axes.

3.Thedesign of the square center cut-out

allows for the mounting of glass plates for sample loading.

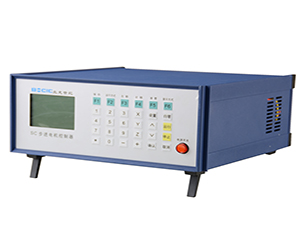

4.The controller uses standard RS232 interface

5.Zero position photoelectric switch is

included. Travel limit switches are located at both ends of the stage for accurate positioning and protection.

- description

- parameters

|

Model |

MTMS101 |

MTMS102 |

MTMS103 |

MTMS104 |

|

|

Travel(mm) |

X-axis |

30 |

50 |

100 |

150 |

|

Y-axis |

30 |

50 |

100 |

150 |

|

|

Maximum optical size (mm) |

70×70 |

60×60 |

138×138 |

163×163 |

|

|

Table sizeA×B(mm) |

200×200 |

155×155 |

300×300 |

350×350 |

|

|

Optical sizeC×D(mm) |

88×88 |

90×90 |

188×188 |

238×238 |

|

|

H(mm) |

80 |

35 |

80 |

80 |

|

|

Mounting holeX×Y (mm) |

100×50 |

125×50 |

200×150 |

250×200 |

|

|

Size E×F(mm) |

275×310 |

254×254 |

375×410 |

435×465 |

|

|

Screw pitch(mm) |

1 |

1 |

4 |

4 |

|

|

Resolution(mm) |

0.000078 |

0.0032 |

0.00032 |

||

|

Resetting positioning accuracy(mm) |

<0.003 |

<0.005 |

|||

|

Stepper motor(1.8°) |

42stepper motor |

28 stepper motor |

42 stepper motor |

||

|

Loading capacity(kg) |

10 |

5 |

20 |

20 |

|